Silicone Rubber Keypads

KEYPADS: Rubber Keypads

We have a long-term experience in customized rubber keypads of over 30 years. So please be invited to our experience and know-how in this field and kindly contact us for your project.

Silicone Rubber keypads were originally developed for the electronic industry as an economical alternative to discrete switches.

In the meantime silicone rubber keypads are one of the most widely used switch technology in the electronic industry.

You find it in all applications like industry, automotive, measurement, medicine, military, agriculture, consumer products and many other applications. Due to their high reliability, long lifetime, good tactile response and very robust characteristic.

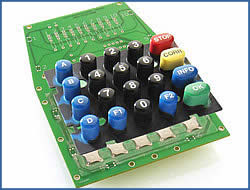

Silicone rubber keypads are very flexible in their design, tactile haptic, colours, different surface coatings like Epoxy, PU, plastic/metal caps which can increase the abrasion resistance, the UV resistance and chemical resistance.

The rubber can be manufactured in all colours, including metallic-effects. So each key can have their own colour.

Stroke and operating force can be adjusted at a wide range depending on customer’s requirements. Multiple switching-functions are also possible like rocker switches.

In combination with customer housing a protection class up to IP68 can be realized.

Due to translucent silicone in combination with laser etching you can backlight the keys one by one or as a complete design.

There existing various solutions for the electrical contacts of the silicone keypads like silver ink (low cost), carbon pills, metal domes or only silicone.

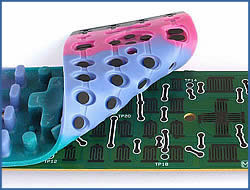

Nowadays you can get the silicone keypads in combination with a membrane switch.

So you have the haptics of rubber keypad and the advantage of a membrane switch like you can glue it on the surface of your application and contact it by a ZIF connector via tail. So you need no PCB direct behind the keypad in your application.

Silicone rubber keypads advantages are:

- More than 1 million key clicks up to 10 million possible

- Minimum abrasion possible with Epoxy/PU coating

- High resistance to dirt fluids, chemicals and thermal influences

- Actuation force can be adjusted from 20g to >500g

- Stroke 0,2mm to > 5,0mm

- Wide operating temperature -40°C to +250°C possible.

- Very small risk of maininance

- Flexible

- Shape, colour and backlight easy to realize

...Please test us - we would like to support you!